cam and tappet experiment

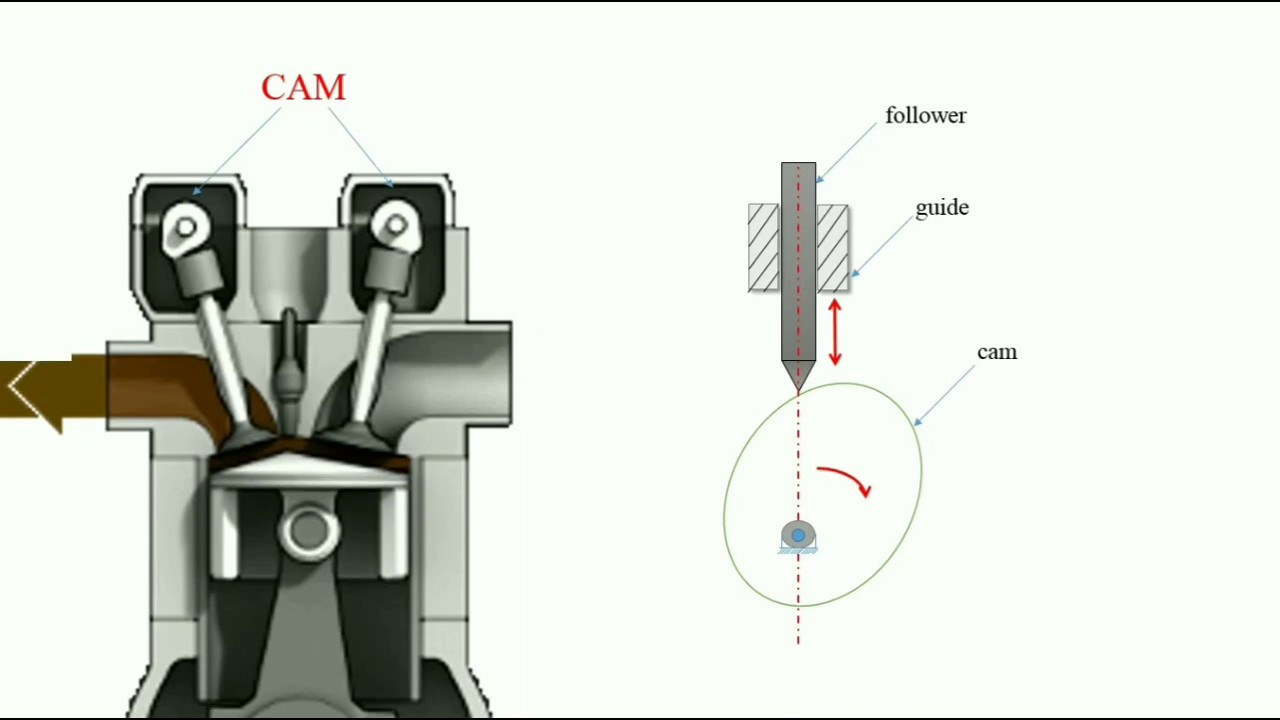

Follower inhibits the push and pulls of the Cam. CAM AND TAPPET MECHANISM OBJECTIVES.

What Are Cam And Follower Types Working Terminology Application Notes Pdf

The bowl is connected in turn to a tappet lever E link rods G links J and a heald shaft K.

. In the present study. Cam and tappet mechanism Graph Paper Tape. A follower is used to transfer.

CAM AND TAPPET EXPERIMENT Objectives The objectives of this experiment are. Considering the simplicity cost and packaging a flat tappet was widely applied in the valve train of a double overhead camshaft diesel engine with high speed and heavy duty. Each tappet is separately connected to a heald shaft through link rods and tappet.

Tappets are generally used for heald shedding. The head casting and the camshaft were shortened so that only two journal bearings remained. Statement of Purpose Objective.

There are five types of cams used that is convex tangent. The surfaces of tappet inserts subjected to lubricated moving contact in a camtappet friction apparatus have been analyzed by IR reflectionabsorpti. Day and Date experiment performed.

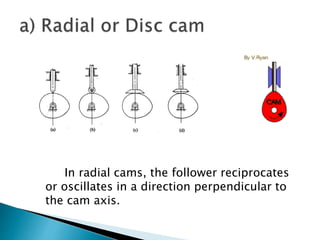

The experiment is conducted with different types of cam which is simple harmonic cam and constant acceleration cam respectively. A mechanical constraint cam also be introduced by employing a dual or conjugate cam in arrangement similar to what shown in Figure 6-7. The plot for the harmonic cam is in the form of a cosine wave.

The jerk for this cam is therefore zero. Situated on the rear of the cam. Tappet is a type of cam to which a.

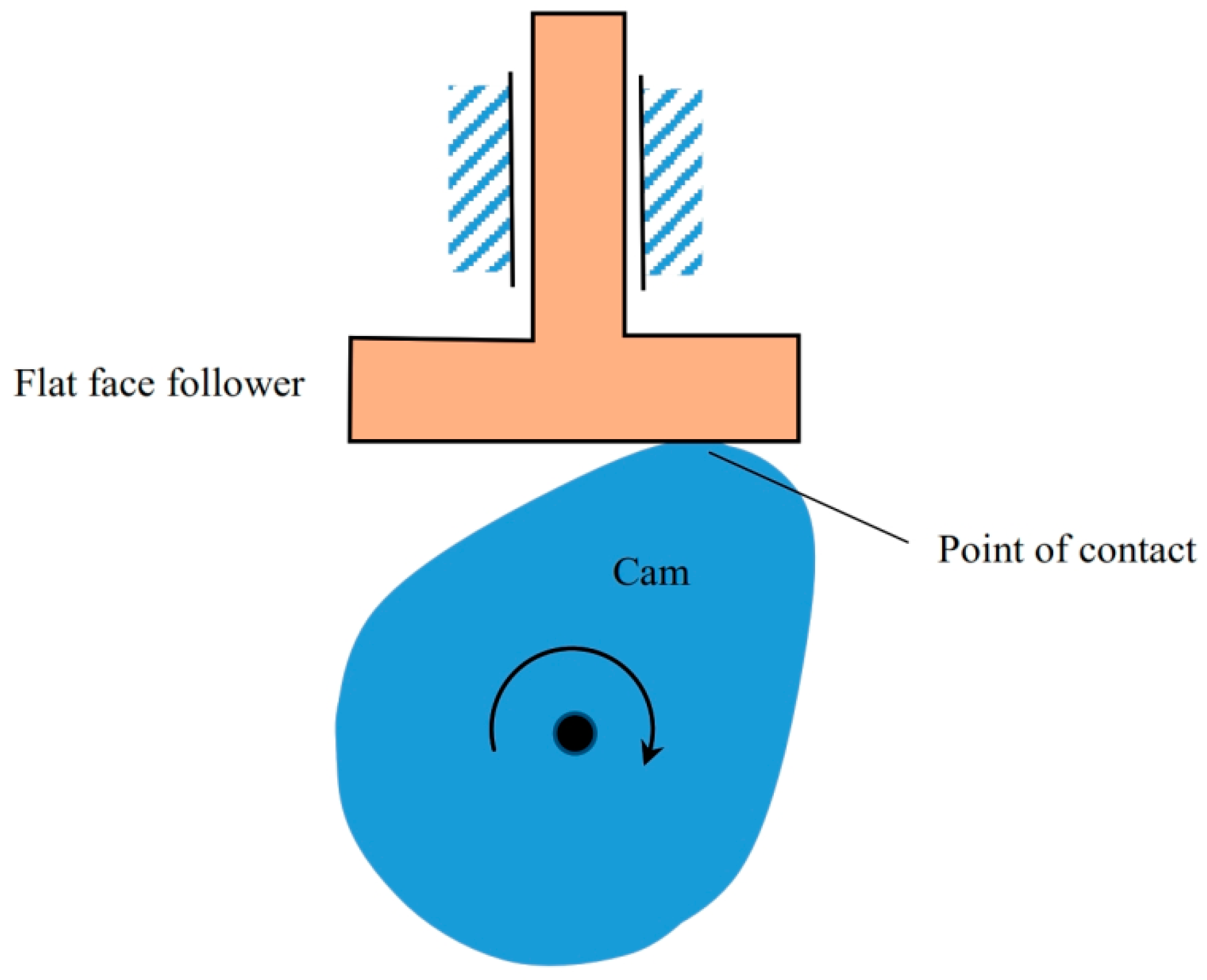

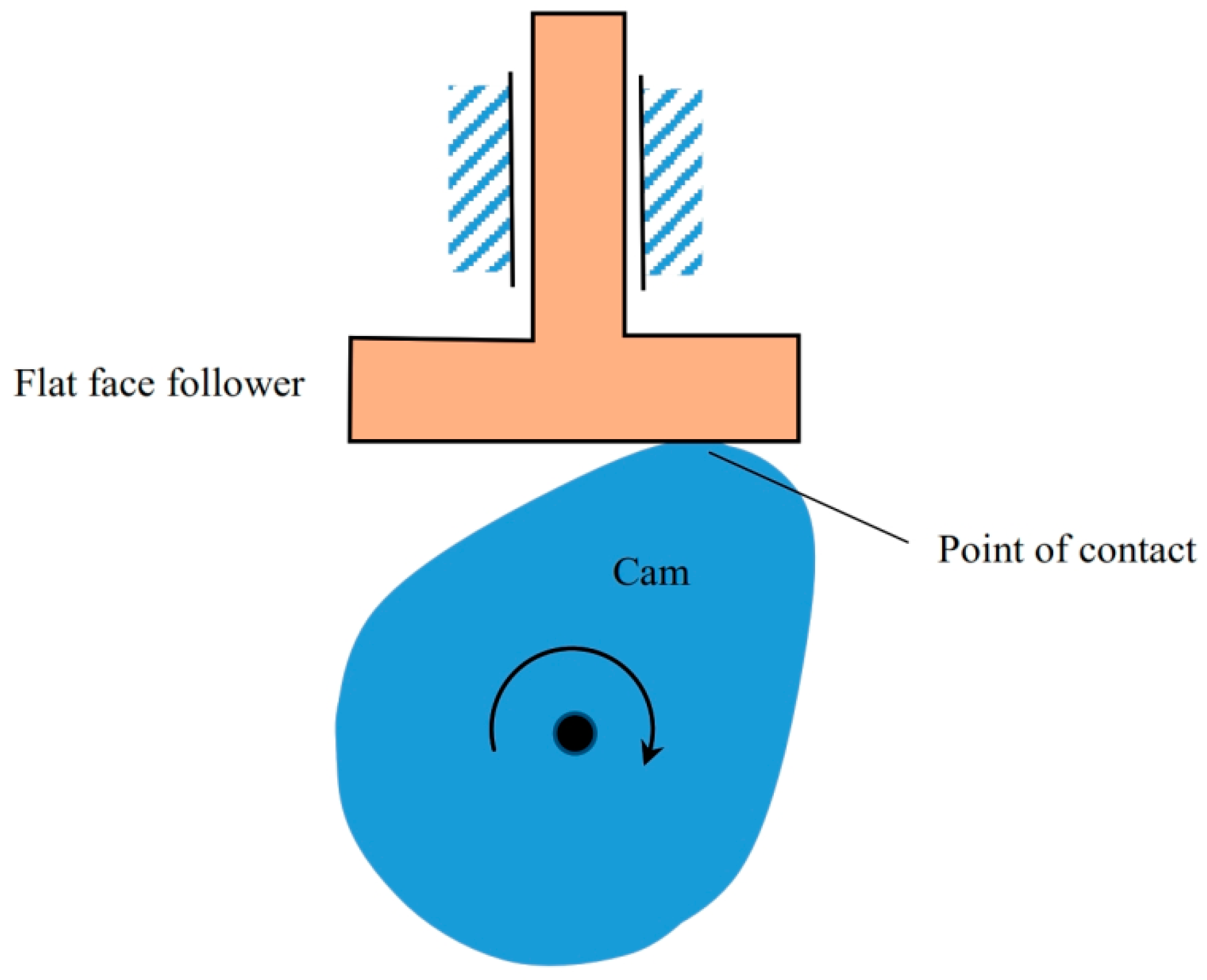

Title cam and tappet analysis. Assuming that there is a line contact between the cam and tappet the Hertz formula for calculating the contact. The objective of the experiment is to.

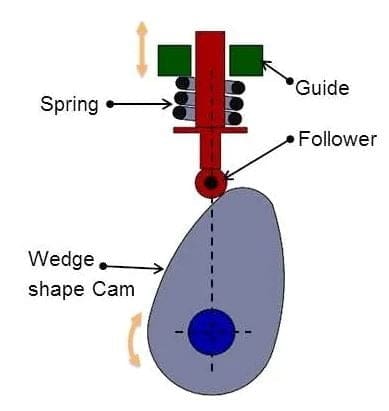

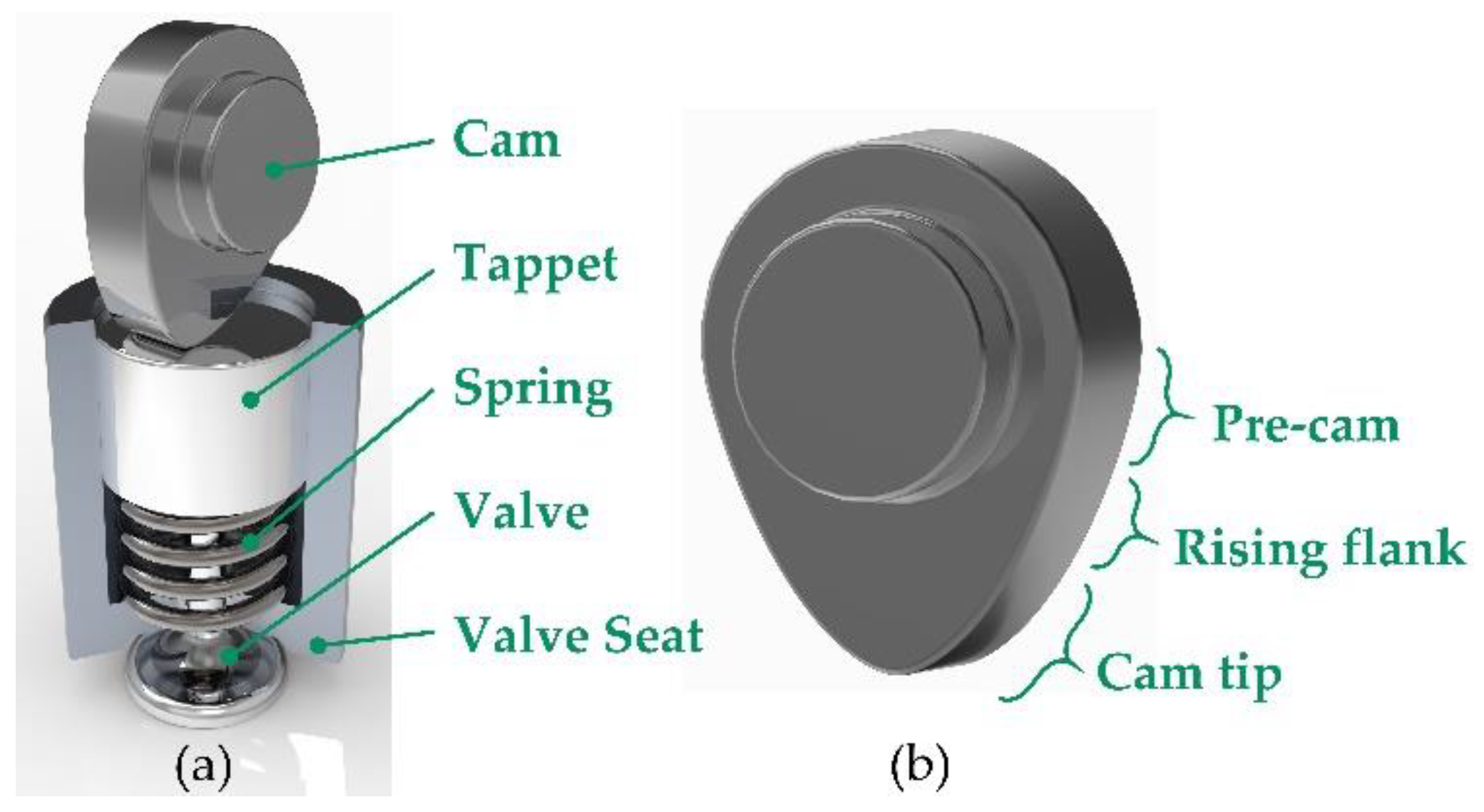

The cam and tappet are usually cylinders made of different metal materials. 13 Tappet 23- fixing screw 14-Interchangeable pick-up flat or cylindrical 16-Belt drive for the recording drum 24- knurled nut fixing the cam Fig. To draw and analyze the design of a cam and tappet mechanism.

The jerk for this cam is therefore in the form of a sine wave the same as the velocity. The results showed that for the particular geometry tested tappetbore friction torque accounted for about 13 of the total camtappetbore friction torque at 250 cam rpm. Study on gearing mechanism of tappet loom.

Camtappet wear is one of the most difficult reliability and durability problems to predict during the development of a prototype engine valve-train system. A follower is a mechanical component concerning which the Cam rotates in an oscillatory or circular motion. - Investigate tappet.

43 reported that hydrogen-free. To compare the throw profile of two types of cams simple harmonic parabolic cam. A camtappet friction rig was constructed from a 16 L Ford valve train.

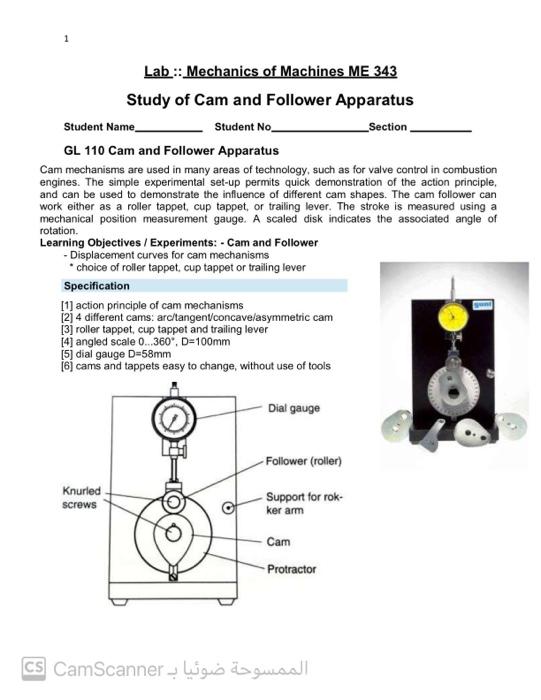

Cam and Tappet by Af idiahaisyah Salleh Submission date. The apparatus used is the cam and tappet apparatus with roller domed and flat followers equipped with dial indicator. The engine vibration and noise induced by a valve train element are analyzed through the modeling and experiment method.

1 Front View of Apparatus The following. 1 For the first part of the experiment the flat follower. The contact force model for the camtappet interface.

The TEHL camtappet-contact of the valve train represents another engine component with high frictional losses and a high amount of sliding. View Experiment 3 _ Cam and Tappetpdf from MECHANICAL MEMB331 at Tenaga National University Kajang. Asif Ahmed Safwan - 1857.

Loosen the fixing screw 23 with the provided Allan key and insert the flat tappet followeApply a thin film of grease to the flat tappet. Each cam has its own roller but the rollers. Universiti tenaga nasional college of engineering department of mechanical engineering memb331 machine design cad lab exp.

Solved 1 Lab Mechanics Of Machines Me 343 Study Of Cam Chegg Com

Cam Tappet Contact Force Download Scientific Diagram

Schematic Of A Cam Tappet Contact Configuration Download Scientific Diagram

Lubricants Free Full Text Understanding Friction In Cam Tappet Contacts An Application Oriented Time Dependent Simulation Approach Considering Surface Asperities And Edge Effects Html

Lubricants Free Full Text Lubrication Analyses Of Cam And Flat Faced Follower Html

Under Picking Mechanism Features Parts And Uses

Beat Up Mechanism In Weaving Motion

The Motored Single Cam Rig A Photograph Of The Rig B 2d Schematic Download Scientific Diagram

Cam And Follower Definition Types Working Principle And Applications Pdf Learn Mechanical

Crimp Percentage Result Analysis Of Woven Fabric Woven Fabric Fabric Weaving Machine

Cam And Follower Types Working Nomenclature Diagram Pdf

Cam Profile An Overview Sciencedirect Topics

Cam Follower Mechanism Mechanical Kinematics Engineering Cam Gtu Youtube